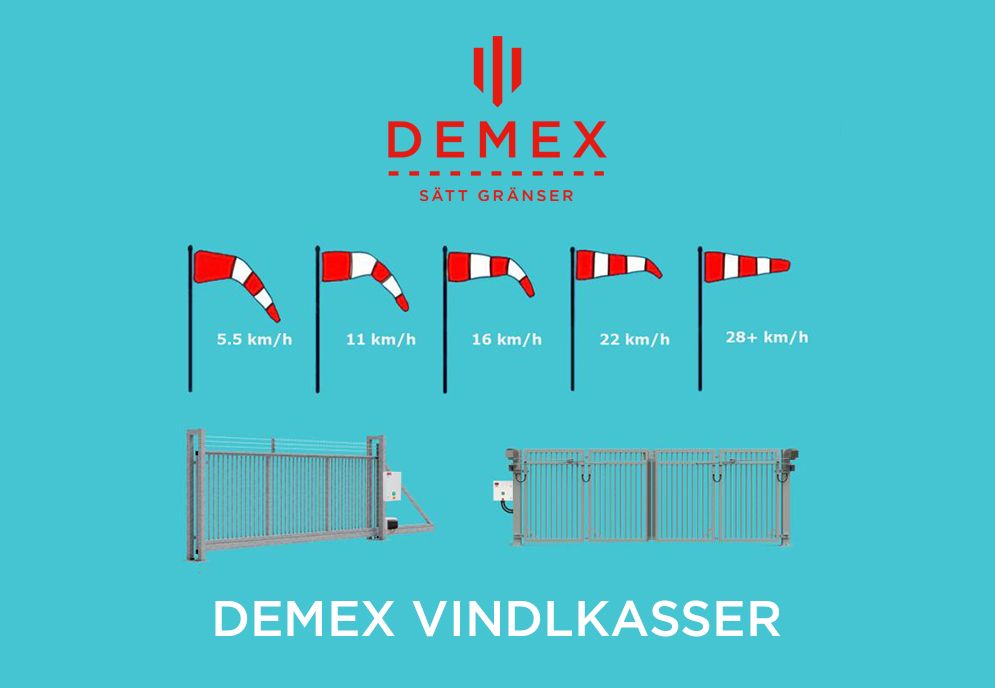

How Demex builds world-class gate automation | Part 1 of 6

With over 30 years of experience, Demex is a leader in the development of innovative and reliable automatic gate solutions. In a 6-part blog series, Vlado Golemovic, Demex automation expert, explains in detail the features and construction of Demex gate automation.

In the harsh climate of the North, extreme demands are placed on durability and reliability when it comes to motorisation and automation. Cheaper imported products are often not adapted to cold winters and harsh weather conditions, and Vlado Golemovic points out that these products often prove to be more expensive in the long run.

“Demex motto is reliable products that can withstand harsh climates. My personal motto is: to create something sustainable, you have to know the product from the ground up. Many fail to do this,” says Vlado Golemovic, who, thanks to his 29 years in the industry, has an in-depth knowledge of the requirements and expectations of motorised gates.

To ensure that gates maintain their performance, Demex gate automation offers advanced maintenance features. These features monitor the performance and condition of the system and include monitoring and warning systems that signal when service is needed. Maintenance monitoring automatically keeps track of the number of manoeuvres the gates have performed, providing an important indicator of when maintenance may be necessary.

“By monitoring openings and closings, technicians can anticipate wear and tear on mechanical parts and schedule regular maintenance before problems occur. The warning system can be set to notify when a certain number of cycles has been reached, giving you an alert that an inspection is necessary,” explains Mr Golemovic.

Proactive Maintenance

The warnings are displayed both visually and audibly, allowing staff to recognise the need for service even when they are not directly at the gates. Proactive maintenance helps to minimise the risk of unplanned downtime and ensures that the system continues to operate efficiently.

“When we started developing our gates, the features and components we needed were not available. We had to look to other suppliers to build motors and gearboxes that would last. Today, we develop and manufacture ourselves, which ensures that our standards remain high.”

The warnings are displayed both visually and audibly, allowing staff to recognise the need for service even when they are not directly at the gates. Proactive maintenance helps to minimise the risk of unplanned downtime and ensures that the system continues to operate effectively.

“When we started developing our gates, the features and components we needed were not available. We had to look to other suppliers to build motors and gearboxes that would last. Today, we develop and manufacture ourselves, which ensures that our standards remain high. It’s about our customers being satisfied and getting what they have ordered, and that includes several important parameters. I will go through them one by one in the following parts of the series.”

Discover our automated gates here and follow along for the next part of the series!